For businesses importing and exporting across countries, navigating the choppy seas of the international supply chain has been difficult for some time now.

Delays, product shortages and rising costs continue to interrupt businesses of all sizes. Can you relate?

Are you still worrying about your supply chain? Do you think about what you will be facing in the next few months? Do you know the main challenges of managing your supply chain?

To get a better understanding of the impact on business importers and exporters, keep reading to know more about the challenges and what you can do in 2022.

Challenge 1: China’s Zero-Tolerance Policy

China’s outbound shipments in 2021 surged 30% to a record high of more than $3 trillion.

However, things are changing.

After detecting some Omicron variant cases in Shenzhen and Ningbo since mid-December of 2021, Beijing has imposed stricter policies at the key port cities including Shanghai, Dalian, Tianjin and Shenzhen. They are gateways for the trade of electronics, furniture and clothes to meet the strong demand around the world.

The zero-tolerance policy means more than just lockdowns, contact tracing and quarantines. It cuts off important lifelines for businesses and adds congestion at ports threatening the already strained global supply chains.

Challenge 2: Container Shortages & High Shipping Costs

For a long time, 90% of items used to travel by sea, which was cheap and reliable.

Not anymore.

A shortage of shipping containers is contributing to the surge of shipping costs and supply chain disruptions. Normally the containers would circulate the world but today many of them are stuck in North America.

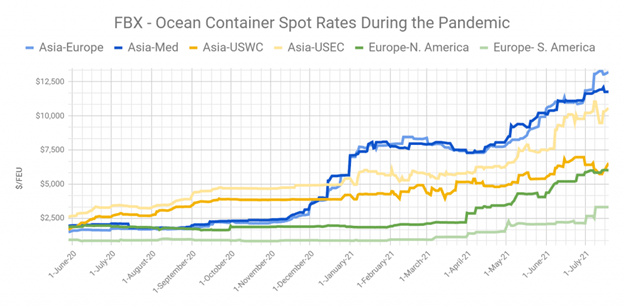

The average cost of shipping a 40-foot container from China to the West Coast of the US has roughly quadrupled in the past year.

- In August 2019, the avg cost was around $1,326.

- In August 2020, it rose to $3,224.

- By August 2021, it had skyrocketed to $18,425.

Despite some easing in recent months, international shipping costs are likely to remain high in 2022.

Challenge 3: Labor Shortage

Technological improvement has reshaped manufacturing and logistics, but there is still a high demand for workers to pick, pack, and deliver goods door by door. Lockdowns and quarantine resulted in a labor shortage.

The government’s fourth-quarter list of 100 jobs with the greatest labor shortage showed manufacturing-related positions accounted for 36, or more than one third. The shortage of workers jumped from 929,000 in Q4 of 2020 to 1,005,000 in Q1 of 2021.

This situation is nothing new to the West.

In the UK and the US, worker shortages are particularly obvious in the shipping and warehousing industry.

Case in point, due to strict quarantine policies and worsening working conditions leading to Great Resignation, warehouses and docks are highly understaffed, causing delays in distribution and turnaround.

Challenge 4: Less Purchase Intention

Deprived of vacations and dining out, more and more Americans adjusted their spending by filling their houses with PPE, home gym equipment, kitchenware and electronics.

Online fitness sessions and video games may be the hot topics shortly. Some experts predict that as vaccination rates keep rising and life is regaining more normalcy, Americans will again shift their spending — from physical goods back to experience.

What you should do?

As a business owner, what can you do to manage your supply chain with minimum risks and input?

- Diversify Suppliers to Balance Risk

The very first thing on your list is to partner with more suppliers to ensure your production lines are on track. You can’t just solely depend on that one factory you’re used to. If COVID happens where it’s located, your production line can go awry at any moment.

Moreover, keep in mind that the manufacturing industry in China is and will be stronger and more developed. It’ll be easier in the future to make your product for less time, but higher quality.

- Keep Your Customers Up to Date

Everybody should expect an extended period of disruption.

Ensure transparency with your clients in these turbulent times by being honest with them about lead time and potential disruptions. You may also start a conversation with them about their questions and concerns.

In addition, you can consolidate your brand by more exposure on social media. Let people tell you what they need. In this case, you can facilitate the production process with more product details.

- Prepare for Safety Stock

Safety stock is a precautionary quantity of product kept in inventory for unanticipated shortages and unexpected delays. It’s an effective insurance policy against stockouts.

Not only do stockouts lead to direct sales loss, but also they damage brand reputation and customer loyalty. When your customers can’t get what they want for just once, they can easily kiss you goodbye and find an alternative.

In this way, being well-prepared for a safety stock will keep you posted on market demand.

A Trusted Supply Chain Management Partner in China

In an increasingly complicated world, keeping track of all your shipments around the world is not easy.

For things that require improvement, you need to rethink the way you manufacture and transport.

As a supply chain management provider and OEM manufacturer in China, China2West has full knowledge and expertise to offer exceptional service and goods delivery services.

We know how the system works, and we are proud of the last 16 years of service we’ve provided in China. Contact us today!