Our Inspection Standards

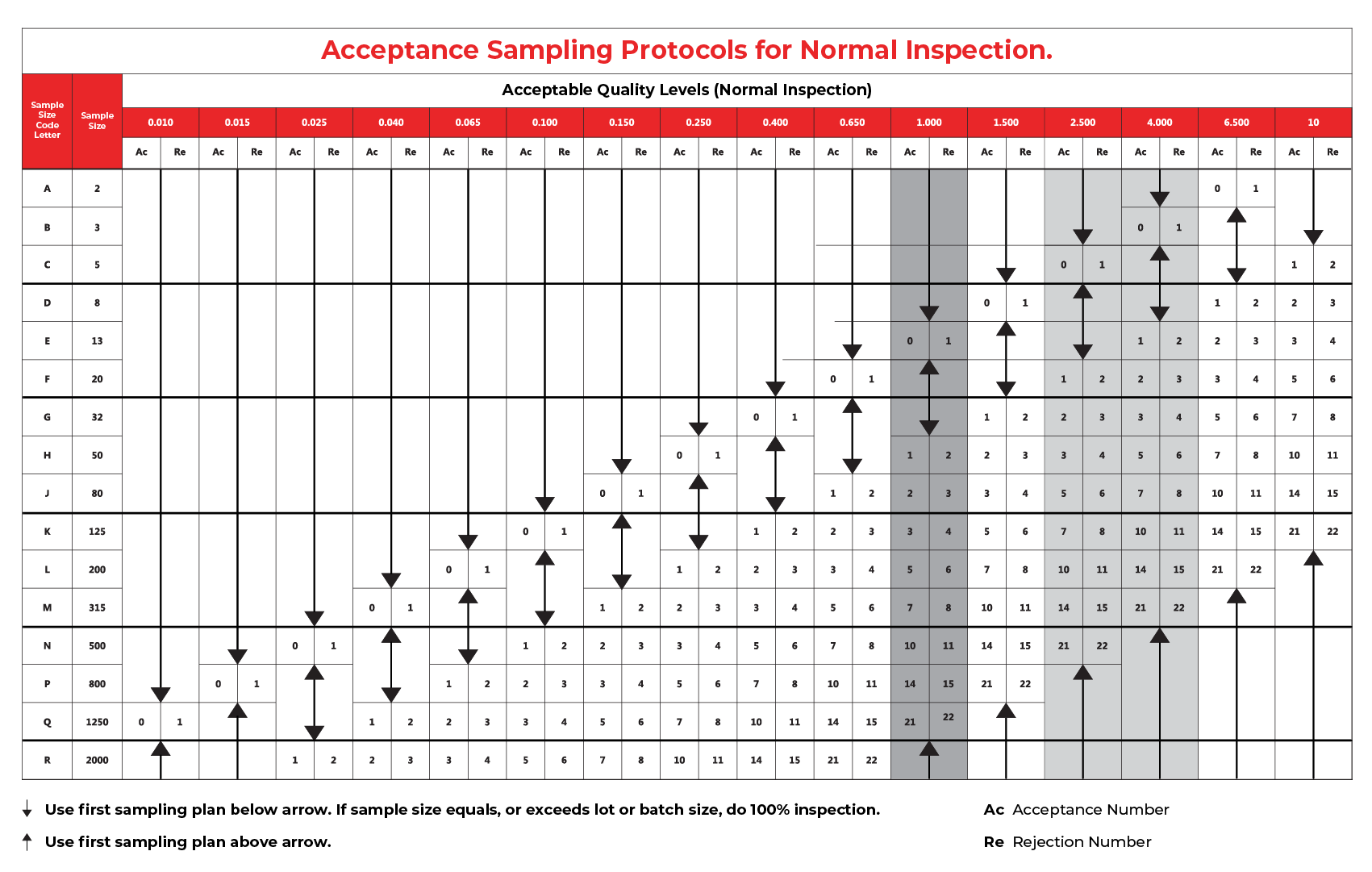

C2W Quality Inspectors use uses the recognized international Quality Control standard ISO 2859-1 (ANSI/ASQC Z1.4-2003), also known as the AQL Tables to measure acceptable levels of quality during their routine product inspections.

The AQL (acceptable quality level) can be set to an agreed figure for each type of defect that determines clearly the number of parts that are allowed to have certain types of defects before the entire lot is rejected and dealt with by the manufacturer. Levels set are project dependant but in general defects will be judged (as an example) as follows:

1. Safety or Critical Defect (functional included) – the entire lot will be rejected if any safety defect is found. This could be a sharp edge, malfunction or anything that could cause physical injury.

AQL - 0

2. Major Defect – Determined as serious scratches or obvious deformations.

AQL - 1

3. Minor Defect – Dirt, light scratches, minor colour differences and small burrs fall into this category.

AQL - 4